makeCNC and makeCNC workshops would like to announce some Major Changes in the way we package our files. The reason for these changes is because of new development in CAM software meaning we no longer need to create dog-bone fillets in our files and we also no longer need to supply so many scales of files.

So from here on out All makeCNC products will be packaged in the following way:

A folder with assembly guides and, on occasion, numbered DXF files to assist with assembly of the pattern will be provided in each product. Then we will provide another folder which will hold a metric version of the DXF file at a single given scale and an inch version. We provide these in this way now because, with our inexpensive scale calculator program, it is a simple task to scale the drawings up or down to suit the desired thickness of your material. This program comes free with purchases over $150 or it is readily available and only $5 if you need to purchase it.

We will also be providing CDR versions of the files in both metric and inch formats as 99% of laser users have Corel Draw as the software they use to import and deal with our files. These CDR files (Corels Native Format) will be in version 11 so they should open in most any version of Corel Draw including the student version which does not allow DXF import.

For Scroll Saw users we will be adding a PDF version of the files to each product package as well, again in both metric and inch to allow for easy printing of the patterns for adhering to plywood and cutting out the parts with your Scroll Saw.

So there will no longer be two options for purchase. All of these formats we just listed above are included in the one file package. All products released after the June 1st, 2014 will be in this format and we will also slowly be converting all our existing files over to this New Improved Format.

There are now two ways for our customers to deal with Dog-bone fillets and inside corners and we will explain here what they are. If you are a user of Vectric products you will know about the dog-bone fillet features in V-Carve as well as Aspire and you can add your own dog bones to the files using this feature. In this way it is better as you now have control over the size of the fillets. But the most important Good News is that Vectric are soon to release a plugin/gadget that will automatically compensate for inside corners in the tool-path features of the software so it will soon be a simple and automatic process for owners of this software.

But the real reason we completely did away with dog-bone versions in our products is because of the New Release of CAMBAM another CAM software we sell in the makeCNC store that has a New Feature called “Corner Over-cut” which is explained below. You can purchase this powerful CADCAM software at our site for around $149 which is a bargain for all the features it offers the user and they do have a free version that has the corner compensation feature in it.

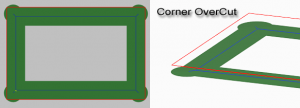

CAMBAM : Corner over-cut option. (dog-bone fillets)

Inside corners, where a tool diameter typically will not fit, can cause problems if they define a shape where another shape needs to be inserted into it, as with a slotted joint or inlay.

A new parameter: Corner Over-cut, set to True or False can be defined, which will add an over-cut in towards these inside corners.

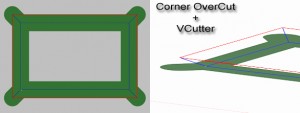

If the Tool Profile parameter for a machining operation is set to V-Cutter, a ramped cut is inserted up to the stock surface, all the way into the inside corner. This can result in nice clean square corners when an appropriate V cutter is used.

The file snap-together-box.cb in the CamBam samples folder illustrates the use of corner over-cuts to clear joints that will be slotted into each other.

The CamBam.cb sample file contains an example of a V corner profile in the last part.